For laboratories striving for reliable, high-throughput tissue processing, the automatic tissue processor offers a compelling solution. By automating the intricate steps of fixation, dehydration, clearing, and infiltration, these instruments minimize human error and ensure consistent sample preparation. This article examines the features and benefits of automatic tissue processors, highlighting their contribution to standardized results, increased productivity, and a safer laboratory environment.

An automatic tissue processor is a laboratory device used in histopathology to prepare tissue samples for microscopic examination. It automates the traditional steps of tissue processing, including fixation, dehydration, clearing, and paraffin infiltration. By using a programmable system, it moves tissue cassettes through a series of reagent stations with precise control over time, temperature, and agitation. This ensures consistent and high-quality sample preparation, which is essential for accurate diagnosis and research.

The automatic tissue processor is especially valuable in high-volume laboratories where time and consistency are critical. It reduces the need for manual labor, minimizes human error, and improves laboratory safety by limiting exposure to hazardous chemicals. Most modern models offer customizable programs for different tissue types and sizes, allowing for flexibility while maintaining efficiency and reliability in routine histological workflows.

Increased Efficiency

The automatic tissue processor can run continuously, even overnight, reducing the need for constant supervision. This increases the throughput of tissue samples and saves valuable time in high-volume laboratories.

Consistency and Reproducibility

Automated systems follow precise, pre-programmed protocols, ensuring uniform processing results. This consistency leads to better-quality tissue samples, which is crucial for accurate diagnosis and research.

Reduced Labor Costs

The automation of tissue processing minimizes the need for manual labor, freeing up histotechnologists to focus on other tasks. This can reduce staffing requirements and allow lab personnel to work more efficiently.

Improved Safety

Automated systems are usually enclosed, which reduces the exposure of lab personnel to hazardous chemicals such as formalin, alcohol, and xylene. This improves the overall safety of the work environment.

Minimized Human Error

Manual tissue processing can be prone to errors due to variations in timing, reagent handling, and temperature control. Automation eliminates many of these human errors, ensuring better and more reliable results.

Standardization

With automated tissue processing, all steps are standardized, ensuring the same processing parameters are used for each batch. This reduces variability between different tissue samples and technicians, improving the overall quality of results.

Time-Saving

The automatic system optimizes processing time, allowing faster turnaround of tissue samples. This is especially beneficial in diagnostic settings where quick results are critical for patient care.

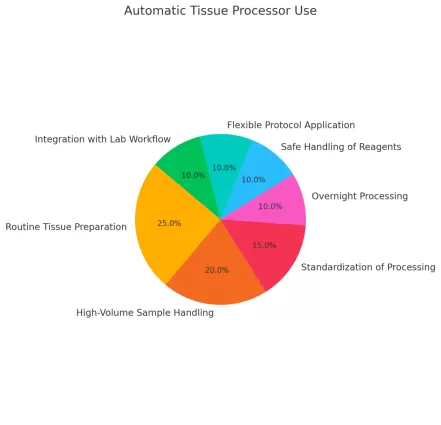

Routine Tissue Preparation

An automatic tissue processor is mainly used to prepare tissue samples for microscopic examination. It completes essential steps like fixation, dehydration, clearing, and paraffin infiltration with precision, ensuring tissue structures are preserved accurately for diagnosis, especially in biopsies and surgical pathology.

High-Volume Sample Handling

These machines are built to handle large quantities of tissue samples efficiently. By processing multiple cassettes simultaneously, they help laboratories meet demanding workloads while maintaining consistent quality. This is especially valuable in hospital settings and large diagnostic labs with daily high-throughput needs.

Standardization of Processing

Automated tissue processors follow preset protocols, ensuring that every sample undergoes the same conditions. This standardization reduces variability and human error, resulting in more reliable and repeatable histology results, which are crucial for maintaining diagnostic accuracy across different tissue batches.

Overnight Processing

Automatic processors can run unattended overnight, allowing tissues to be ready for embedding the next morning. This overnight capability improves lab efficiency, shortens turnaround times for diagnostic results, and helps laboratories manage urgent or time-sensitive specimens more effectively.

Safe Handling of Reagents

By enclosing hazardous chemicals such as formalin and xylene within a sealed system, automatic tissue processors significantly reduce the risk of exposure. This promotes a safer working environment for lab technicians by minimizing contact with toxic fumes and accidental spills.

Flexible Protocol Customization

Modern automatic tissue processors offer programmable options to adjust processing cycles based on tissue type. Whether handling dense, fatty, or fragile samples, the settings can be tailored to optimize processing time and reagent exposure, ensuring the best possible preservation of tissue morphology.

Integration with Lab Workflow

These processors integrate smoothly into existing laboratory workflows. Their automation helps coordinate with other steps like embedding, sectioning, and staining. This streamlined process reduces manual tasks and supports faster, more organized lab operations from sample intake to final slide review.